CMB: The Tool You Need to Efficiently Build Your Simulation Workflows

Building simulation workflows can be complicated. Trying to find and connect different tools to get the results you’re looking for can be inefficient, error-prone, and take up valuable resources, including time and money. To make matters worse, sharing and deploying these workflows to fellow engineers, researchers, and academics tend to involve relying on handwritten notes and scripts that can be difficult to follow and maintain.

Our team understands these struggles first-hand, so we wanted to come up with a better way of managing simulation workflows. Thanks to our years of experience in post-processing and visualization efforts, such as VTK and Paraview, we have developed an open source tool that provides end-to-end support for simulation workflows. Computational Model Builder (CMB) manages pre-processing, post-processing, and visualizations all in one place, and since it was built as a general-purpose tool, it can be easily applied to a variety of domains. The rest of this blog will show a few examples of using CMB to meet the needs of a range of workflows.

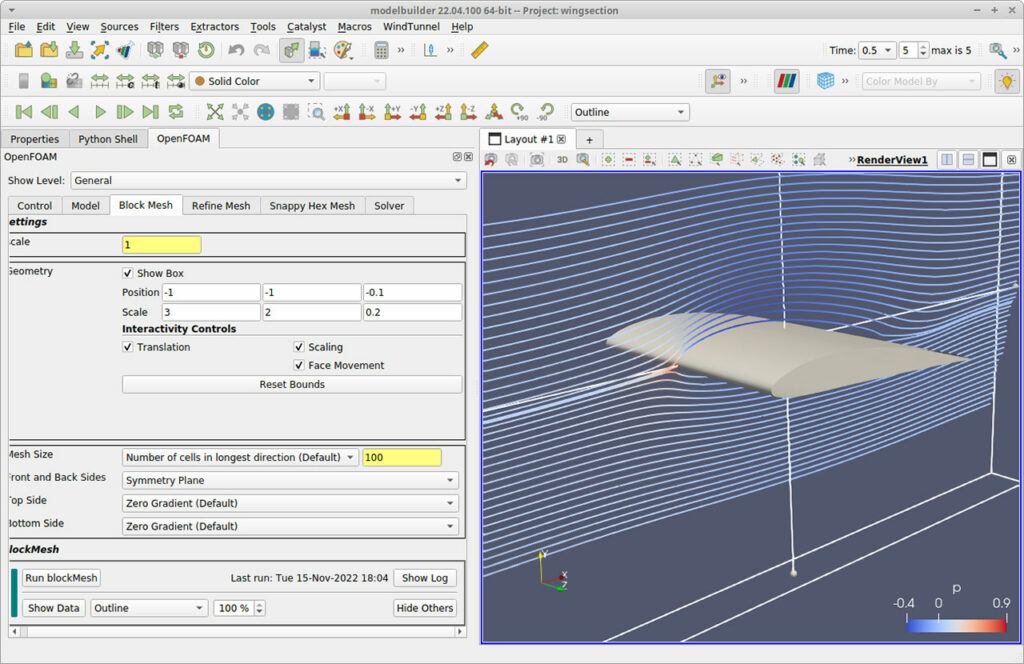

Simulations based on OpenFOAM

Using CMB, we created a windtunnel example (Fig. 1) that allows users to embed faceted geometry into a simple wind tunnel, create the necessary meshes, define the required boundary conditions and material properties, run the solver, and visualize the results – all within the same application. Details on how to download and try out this workflow can be found here.

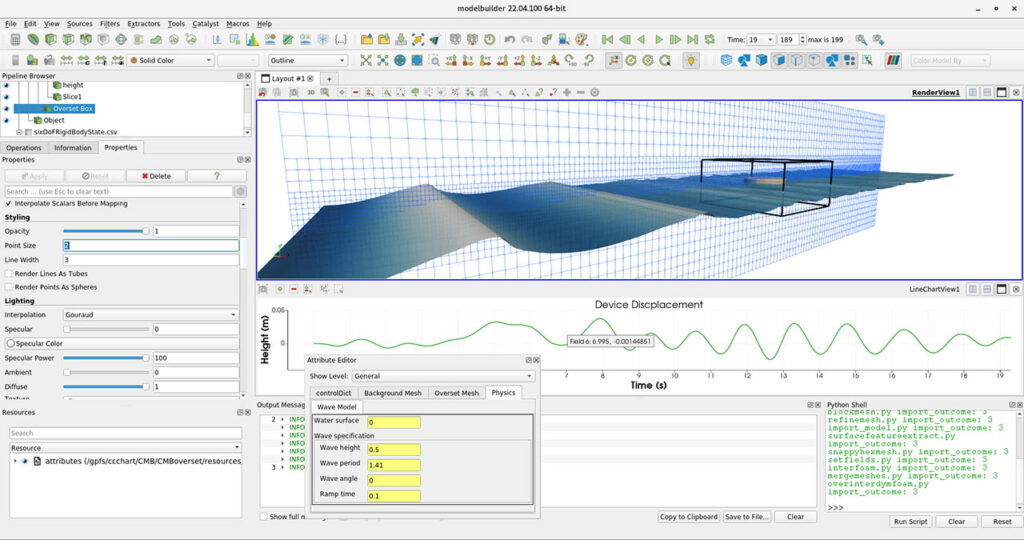

In addition, Kitware has been working with Sandia National Laboratories to use CMB to simulate wave tanks in OpenFOAM (Fig. 2). These simulations evaluate the effectiveness of wave-energy-capturing devices.

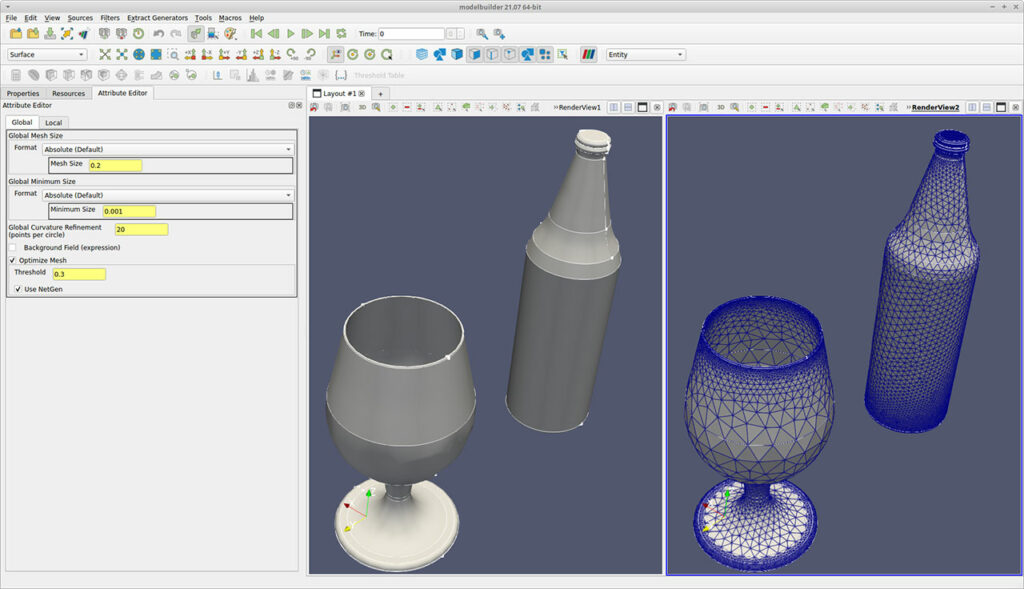

CAD and Mesh Generation Support

CAD and Mesh Generation Support

CMB creates user-friendly graphical interfaces for mesh generation libraries, such as gmsh, as well as solid modeling kernels such as OpenCASCADE , so that they can be used as part of a simulation workflow. Figure 3 shows a CAD STEP file loaded into a CMB application where the user can assign different meshing constraints to parts of the geometry. The user can then generate a mesh using the gmsh library and display the results. While this extended into general-purpose modeling, the focus of this work was on making pre-existing solid models available for discretization, boundary condition assignment, and other preprocessing tasks.

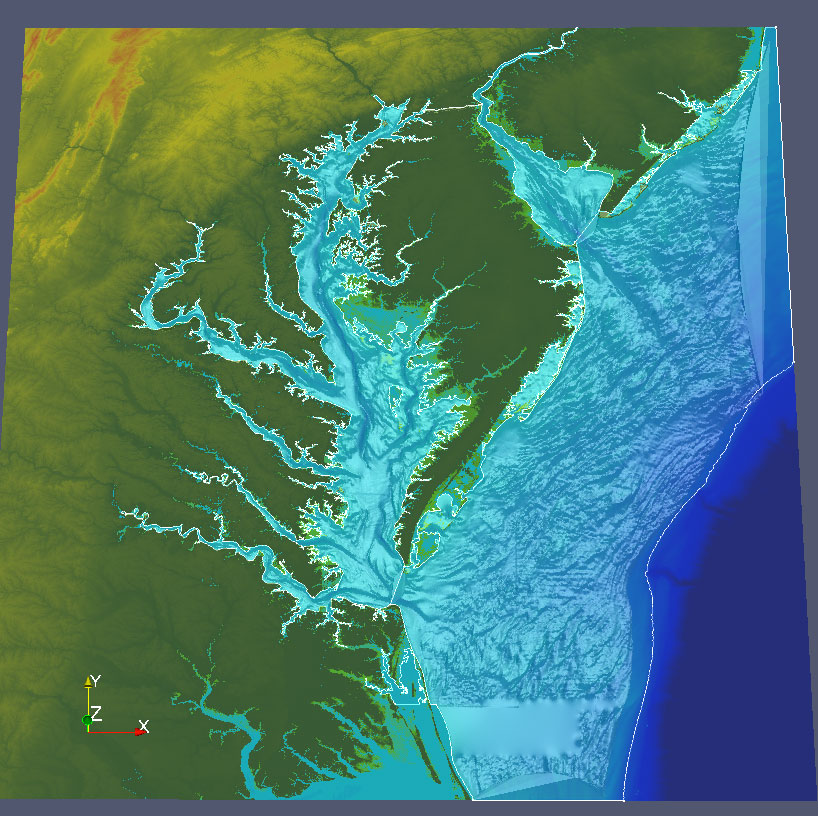

Hydrological Workflows

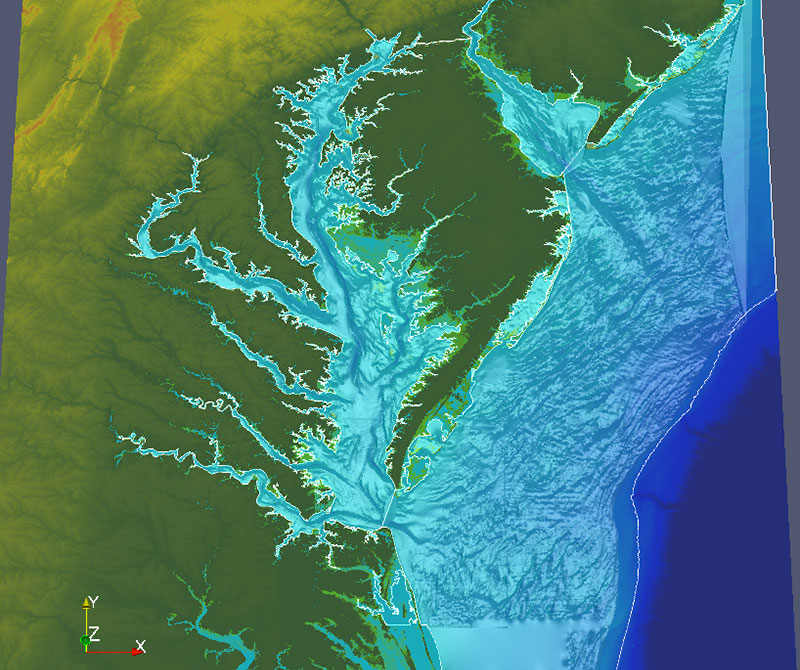

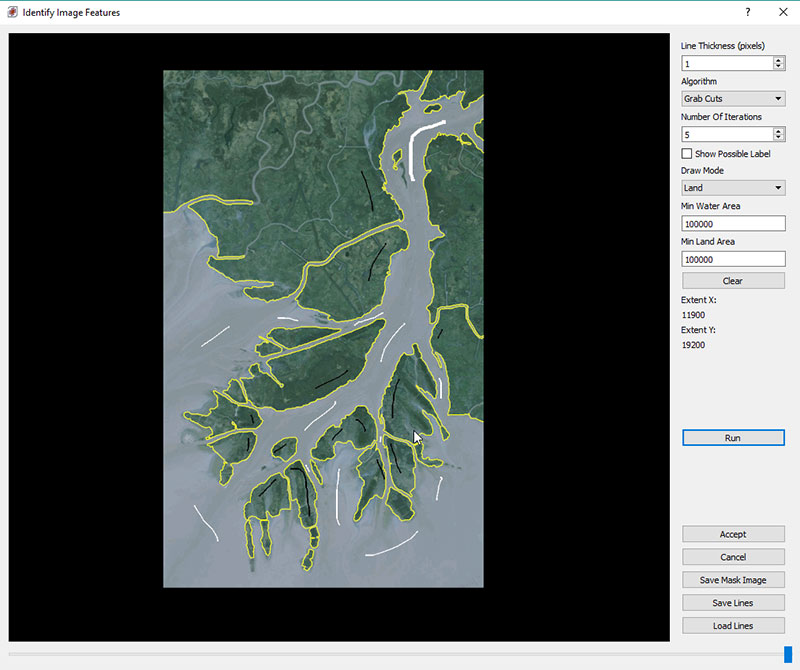

You can use CMB to generate geometric domains for hydrological simulations. The model of the Chesapeake and Delaware Bays in Figure 4 was based on DEM data, while the model of Atchafalaya in Figure 5 was created by combining CMB operations with computer vision-based techniques.

Use CMB for Your Simulation Workflows

CMB is a flexible, open source tool that can be applied to a wide range of simulation workflows. If you would like to specifically discuss your workflow and how you could leverage CMB, send us a message. You can also watch for the next blog in this series to learn more about the key aspects of CMB and its underlying toolkit, SMTK (Simulation Modeling Toolkit).