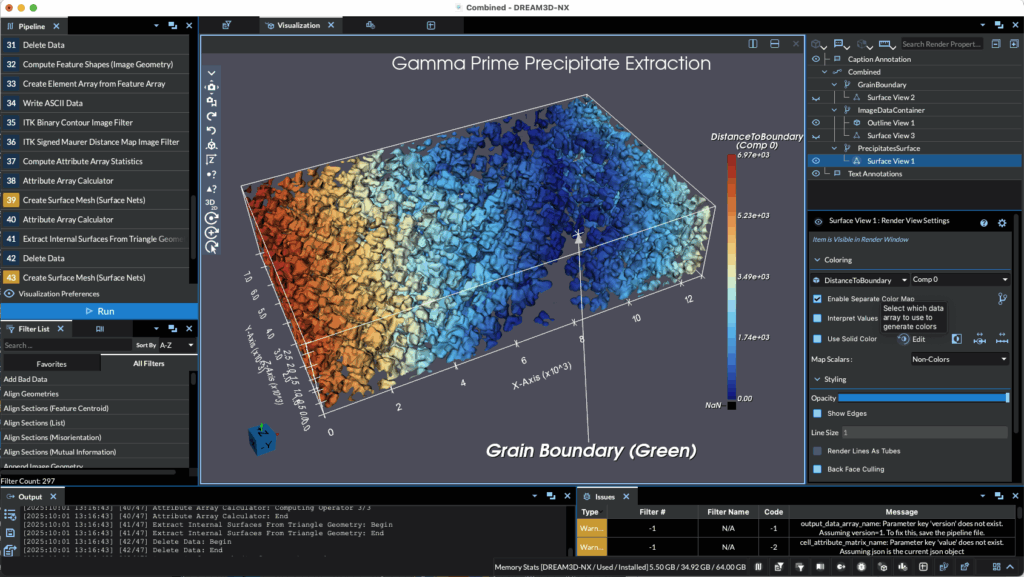

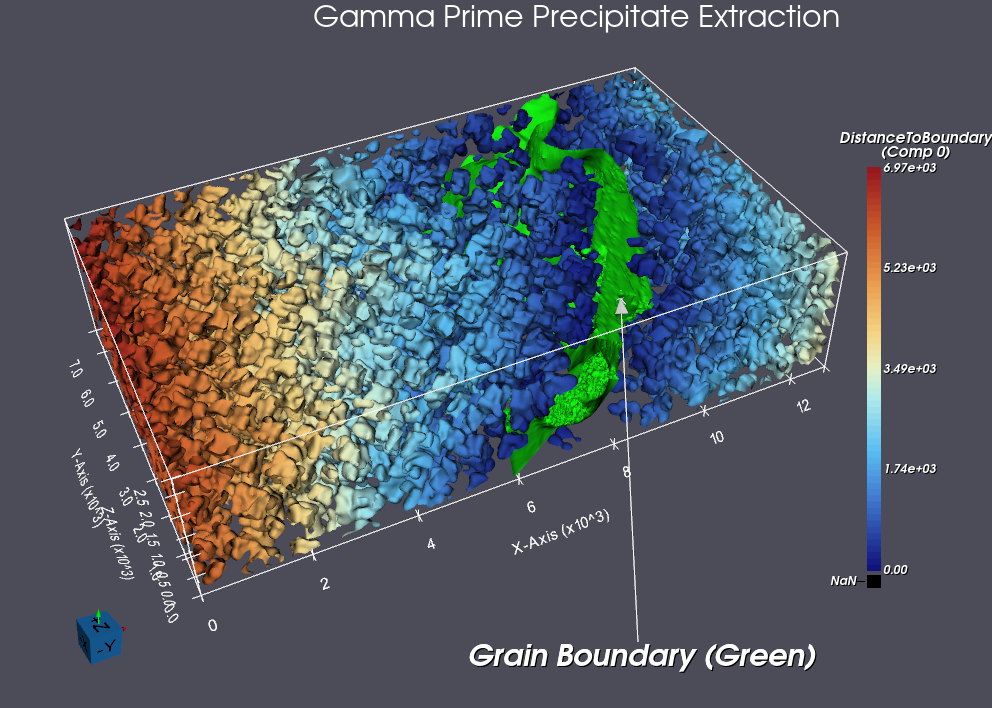

Visualizing the Microstructure: How DREAM3D-NX and VTK Empower Materials Science Research

Materials science thrives on understanding the link between a material’s microstructure and its properties. To truly grasp these connections, sophisticated tools for data analysis and visualization are essential. DREAM3D-NX, a sophisticated data analysis software from BlueQuartz Software, integrates the Visualization Toolkit (VTK) to render materials science data.

The Indispensable Role of 3D Visualization in Materials Science

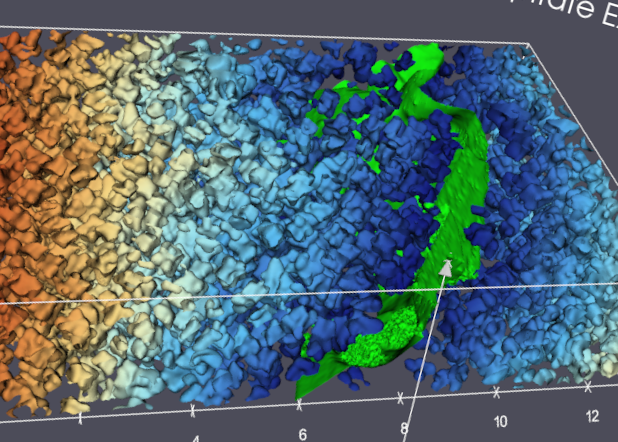

Scientific data in materials science is inherently 3D. Understanding features like grain boundaries, hidden pores, or fiber orientations is difficult with only 2D cross-sections. 3D visualization is critical for a comprehensive understanding.

By transforming raw, often complex, experimental or simulated data into coherent and interactive 3D models, researchers can unlock a deeper level of insight into material behavior and properties. This advanced approach offers several significant advantages:

- Facilitate Intuitive Understanding: Complex geometries, previously abstract or hidden in 2D slices, become immediately clear and tangible in a 3D environment. This allows researchers to effortlessly perceive the spatial arrangements, interconnectivity, and volumetric distribution of various features, revealing patterns and relationships that would otherwise be missed. The ability to rotate, zoom, and interact with the 3D model greatly enhances cognitive processing and reduces the ambiguity inherent in flat representations.

- Identify Defects and Anomalies with Precision: Critical defects such as pores, cracks, voids, and inclusions can be precisely located, quantified, and analyzed within their true 3D environment. This goes beyond simply detecting their presence; it enables the detailed study of their size, shape, orientation, and spatial distribution, all of which are vital for understanding their impact on material performance and failure mechanisms. Such detailed analysis is impossible with fragmented 2D data.

- Observe Microstructure Evolution Dynamically: The study of how microstructures change over time (e.g., during phase transformations, creep, or fatigue) or under varying experimental conditions (e.g., temperature, stress) becomes significantly more informative in 3D. Researchers can visualize the growth of grains, the propagation of cracks, or the rearrangement of phases in a continuous and holistic manner, providing invaluable insights into kinetic processes and material stability. This temporal and spatial understanding is crucial for materials design and engineering.

- Enhance Communication of Findings and Collaboration: 3D visualizations provide a powerful and universally understandable medium for effectively conveying complex research results to peers, stakeholders, and even a broader public. They serve as compelling visual arguments that can bypass the limitations of textual descriptions or abstract graphs, fostering better understanding, facilitating interdisciplinary collaboration, and accelerating the dissemination of knowledge within the scientific community. Interactive 3D models allow for shared exploration and discussion, leading to more productive exchanges and innovative solutions.

DREAM3D-NX and VTK: A Synergistic Partnership

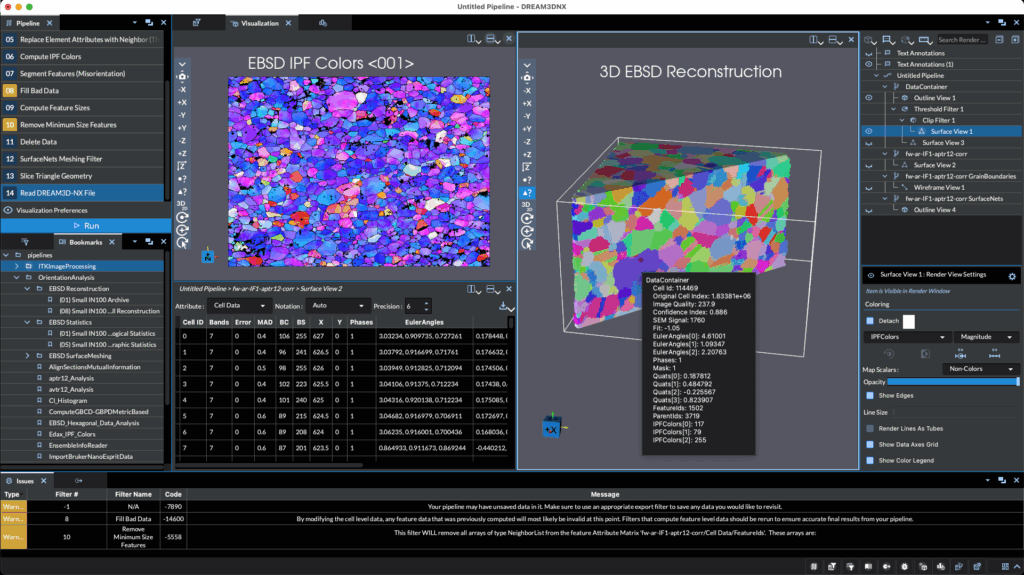

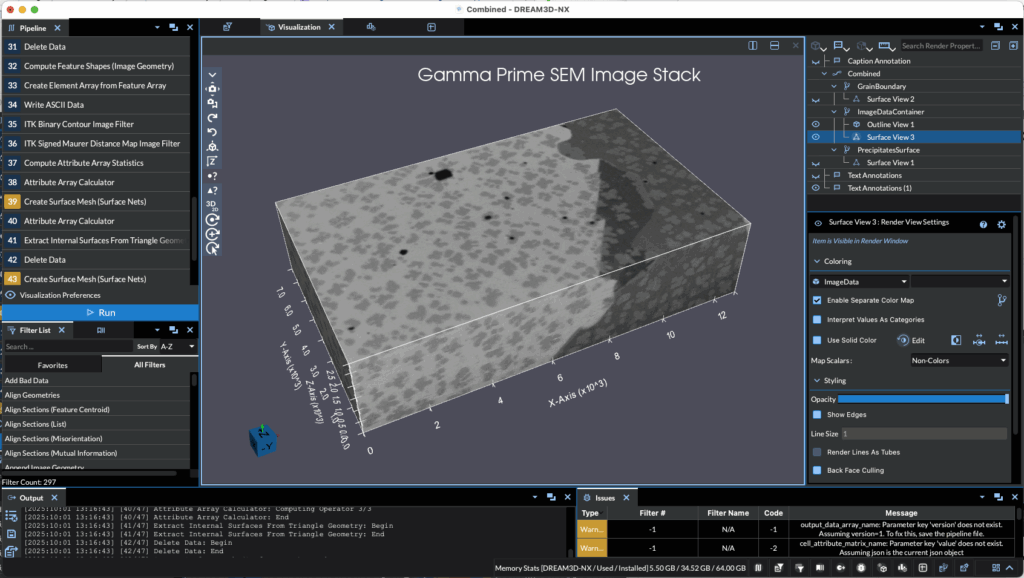

DREAM3D-NX stands as a powerful platform for processing and analyzing microstructural data, derived from diverse sources such as Electron Backscatter Diffraction (EBSD), X-ray tomography, and serial sectioning. The transformative integration of the Visualization Toolkit (VTK) within DREAM3D-NX profoundly enhances its capabilities, offering a comprehensive suite of visualization and analysis tools.

Key Benefits of VTK Integration:

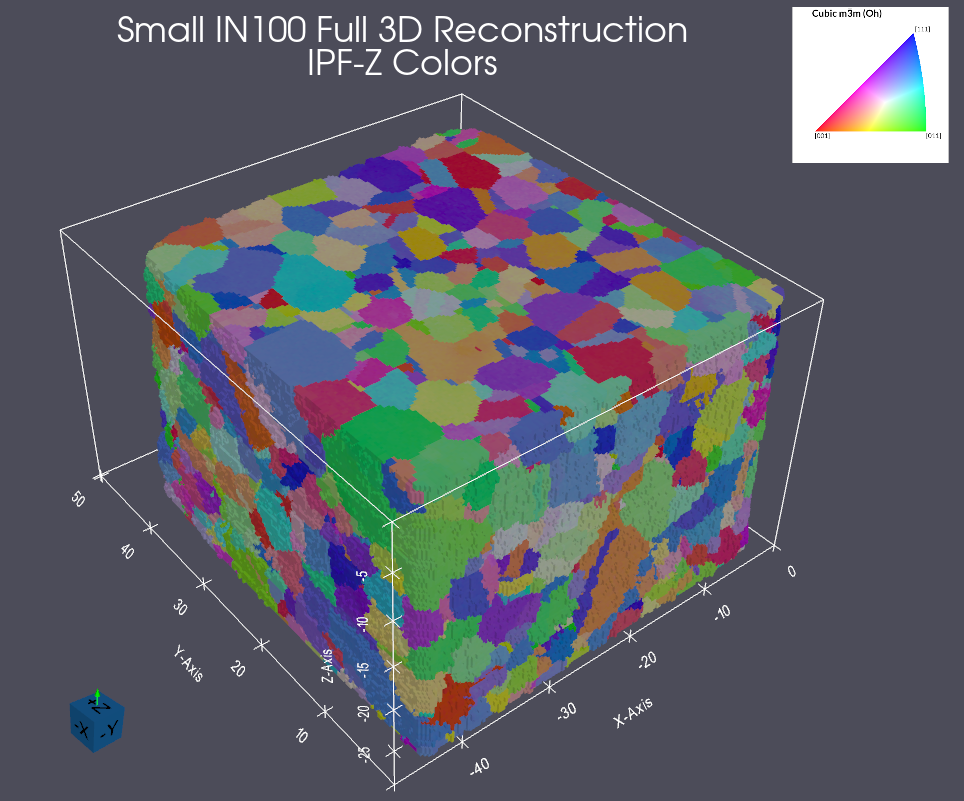

- Render Complex Geometries with Precision: VTK empowers DREAM3D-NX to generate high-quality 3D renderings of a material’s microstructure, ranging from the intricate details of individual grains to the complex interconnectedness of pore networks. This precise visualization allows researchers to gain a deeper understanding of the spatial arrangement and morphology of microstructural features.

- Apply Sophisticated Color Mapping and Shading: Researchers can leverage VTK to assign distinct and meaningful colors to various microstructural features. This includes differentiating between various grain orientations, identifying different phases within the material, or highlighting the distribution of specific defect types. The application of advanced shading techniques further enhances the visual clarity and interpretability of these complex datasets, facilitating easier differentiation and analysis.

- Enable Intuitive and Interactive Exploration: VTK provides a robust framework for interactive data exploration. Users can seamlessly rotate, zoom, pan, and slice through the 3D visualizations, enabling a thorough and dynamic examination of the data from any desired perspective. This interactivity is crucial for uncovering hidden relationships and patterns within the microstructure.

- Facilitate Precise Picking and In-Depth Introspection: VTK’s interactive selection tools allow users to directly click on a specific 3D feature within the rendered microstructure. This action instantly retrieves detailed properties and contextual information associated with that feature, enabling in-depth local analysis and the investigation of individual microstructural elements.

- Efficiently Manage and Visualize Large Datasets: Materials science often involves working with exceptionally large and complex datasets. VTK demonstrates remarkable proficiency in efficiently managing and visualizing these substantial datasets, which is absolutely essential for conducting comprehensive analysis of complex, real-world materials and their intricate microstructures.

- Generate Professional-Grade Visuals for Dissemination: VTK facilitates the creation of publication-ready images and dynamic animations that effectively convey the spatial characteristics and, where applicable, the temporal evolution of the microstructure. This capability is vital for disseminating research findings in scientific journals, presentations, and other professional contexts.

This seamless integration of VTK within DREAM3D-NX ultimately allows for more than just visualization; it fosters interactive data exploration, enables rigorous quantitative analysis, and facilitates the extraction of genuine scientific insights from complex 3D microstructural data, thereby accelerating materials discovery and understanding.

Visual Analytics: Bridging the Gap in Specialized Fields

The synergy between DREAM3D-NX’s robust processing capabilities and VTK’s advanced visualization prowess forms a powerful paradigm for effective visual analytics in materials science. This integration goes beyond merely displaying data; it actively enhances the research process in several critical ways:

- Discernment of Data Relationships: By presenting complex microstructural data in an intuitive visual format, researchers can readily identify intricate correlations between various microstructural features and macroscopic material properties. This visual exploration allows for the rapid recognition of patterns, anomalies, and dependencies that might remain hidden within purely numerical datasets. For instance, the visual representation of grain size distribution alongside mechanical properties can immediately highlight the impact of microstructural evolution on material strength or ductility.

- Facilitation of Hypothesis Generation: The interactive and exploratory nature of VTK-enabled visualization within DREAM3D-NX frequently serves as a catalyst for novel hypothesis generation. Researchers can manipulate and interrogate data in real-time, allowing for “what-if” scenarios and the rapid testing of ideas. This dynamic interaction fosters an environment where new insights into material behavior emerge organically, often leading to research avenues that were not initially conceived based solely on abstract numerical analysis. The ability to visually isolate and analyze specific microstructural defects or phases can lead to new theories about their formation or impact on material performance.

- Enhancement of Data Validation: Visual inspection plays a crucial role in validating the outcomes of computational analyses. When segmentation and characterization algorithms are applied to complex microstructures, subtle errors or inaccuracies can sometimes arise. By visually comparing the raw data with the algorithm’s output, researchers can quickly identify and rectify such discrepancies, ensuring the accuracy and reliability of their computational models. This visual feedback loop is indispensable for refining algorithms and building confidence in the extracted data. For example, a visual overlay of segmented grains on the original microscopy image can immediately reveal misclassifications or under-segmentation.

- Acceleration of Discovery: Ultimately, the seamless integration of DREAM3D-NX and VTK significantly expedites the pace of scientific discovery in materials science. By rendering vast and complex datasets more accessible and understandable, researchers can spend less time grappling with data interpretation and more time focusing on fundamental questions and innovative solutions. This streamlined workflow allows for faster iteration cycles in research, leading to quicker advancements in understanding and developing new materials. The ability to quickly visualize the results of parameter changes in a simulation, for instance, can drastically reduce the time spent optimizing material designs.

Acknowledgements

The authors gratefully acknowledge the financial support provided by USAF Contracts FA8650-22-C-5290 and FA8649-24-P0025.