In today’s era of high-performance computing (HPC), organizations are generating data faster than ever before. Simulations that once took months can now be completed within weeks or even days on exascale systems. But there’s a problem: the process of turning that massive data into insight still lags behind.

Even with powerful computing resources, many teams spend months on post-processing, visualization, and analysis, slowing time-to-market and innovation. The future of commercial HPC depends on bridging this gap, and interactive visual workflows are the key.

The Future of HPC: Faster Decision-making

Traditional HPC workflows are fragmented. Data from simulations, experiments, and AI models often lives in separate tools, handled by separate specialists. This creates silos, inefficiencies, and missed opportunities for collaboration.

Interactive visual workflows eliminate those barriers by integrating every step, from data generation to visualization, into a single, dynamic environment. They transform the way organizations explore, validate, and communicate results by making workflows visual, collaborative, and accessible to both experts and non-specialists.

Through interactive visualization, commercial HPC users can:

- Democratize advanced capabilities — Empower teams across disciplines to analyze, iterate, and innovate without needing deep technical expertise.

- Accelerate expertise transfer — Enable subject-matter experts and engineers to collaborate seamlessly through intuitive, domain-specific interfaces.

- Enhance communication — Visualize data clearly for decision-makers, investors, or partners, translating complex results into actionable insight.

- Reduce time-to-insight — Replace months of post-processing with real-time data exploration and adaptive visualization.

Why Visual Workflows Matter for Commercial HPC

In business-driven HPC environments, speed and scalability aren’t enough. Competitive advantage comes from how fast you can move from simulation to strategy. Visual workflows enable that agility by providing:

- Transparency and traceability — Interactive exploration reveals the “why” behind the results.

- Adaptive decision support — Users can adjust parameters, re-run analyses, or compare outcomes instantly.

- Cross-domain collaboration — Engineers, scientists, and stakeholders can work from the same live data, not static charts or reports.

By aligning AI, simulation, and visualization within a single interactive framework, organizations can shorten product design cycles, improve quality, and unlock new insights from their HPC investments.

Kitware’s Visual Workflow Platform for HPC

At Kitware, we’re redefining how industries harness HPC data through our modular, interoperable visual workflow platform, built on decades of open source innovation.

Our platform combines high-performance back-end frameworks with flexible, run-everywhere interfaces, empowering organizations to deploy custom solutions on desktops, in Jupyter notebooks, or directly on the web.

Core components include:

- VTK and ParaView — Scalable visualization and analysis from laptops to supercomputers.

- SMTK (Simulation Modeling Toolkit) — Asset and attribute management that ensures reproducibility.

- Fides — Streaming of simulation and experimental data at scale.

- Catalyst — In-situ processing that analyzes data as it’s generated, not months later.

- trame — Kitware’s Python-based framework that unifies these components into interactive visual workflows for modern HPC environments.

Our platform is built in C++ (with CUDA, HIP, and SYCL) for optimal performance, and it integrates with Python to make development faster and more flexible. The result: HPC-grade performance delivered through interfaces that anyone, from simulation engineers to data analysts, can use effectively. Together, these tools accelerate the time from computation to insight, enabling faster innovation and smarter decision-making.

Real-World Impact Across Industries

Commercial organizations are already leveraging Kitware’s visual workflow platform to:

- Streamline large-scale simulation analysis for aerospace and energy R&D.

- Visualize AI-assisted engineering design processes in real time.

- Transform complex simulation outputs into interactive dashboards for executives and partners.

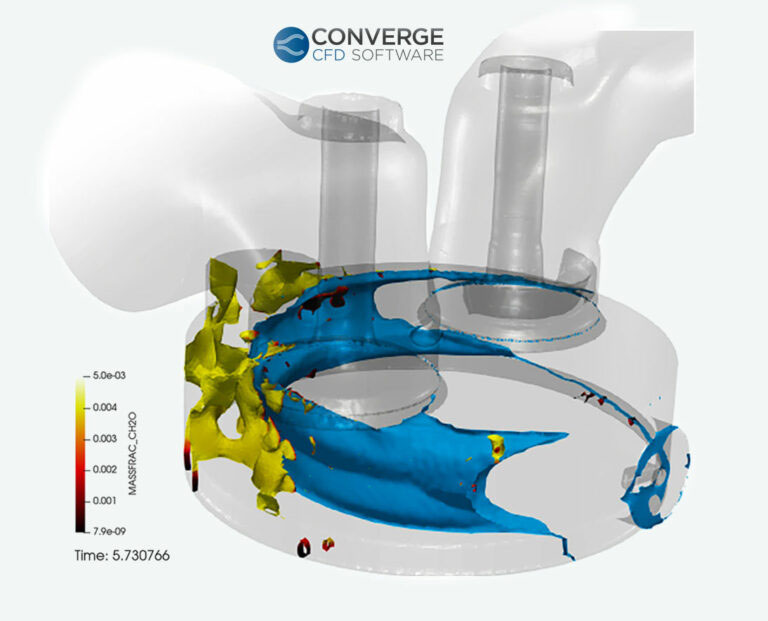

Convergent Science uses ParaView and Catalyst in their CONVERGE software to improve capture of high-speed physical phenomena inside internal combustion engines such as knocking. Catalyst allows saving isosurfaces at a rate much higher than is possible than saving full datasets and can reduce file output from ~100 gigabytes to ~100 megabytes in a typical simulation. Read the blog post

In Situ Data Analysis Brings Faster Results and Accelerated Insights to find out more.

Frameworks used: ParaView, Catalyst

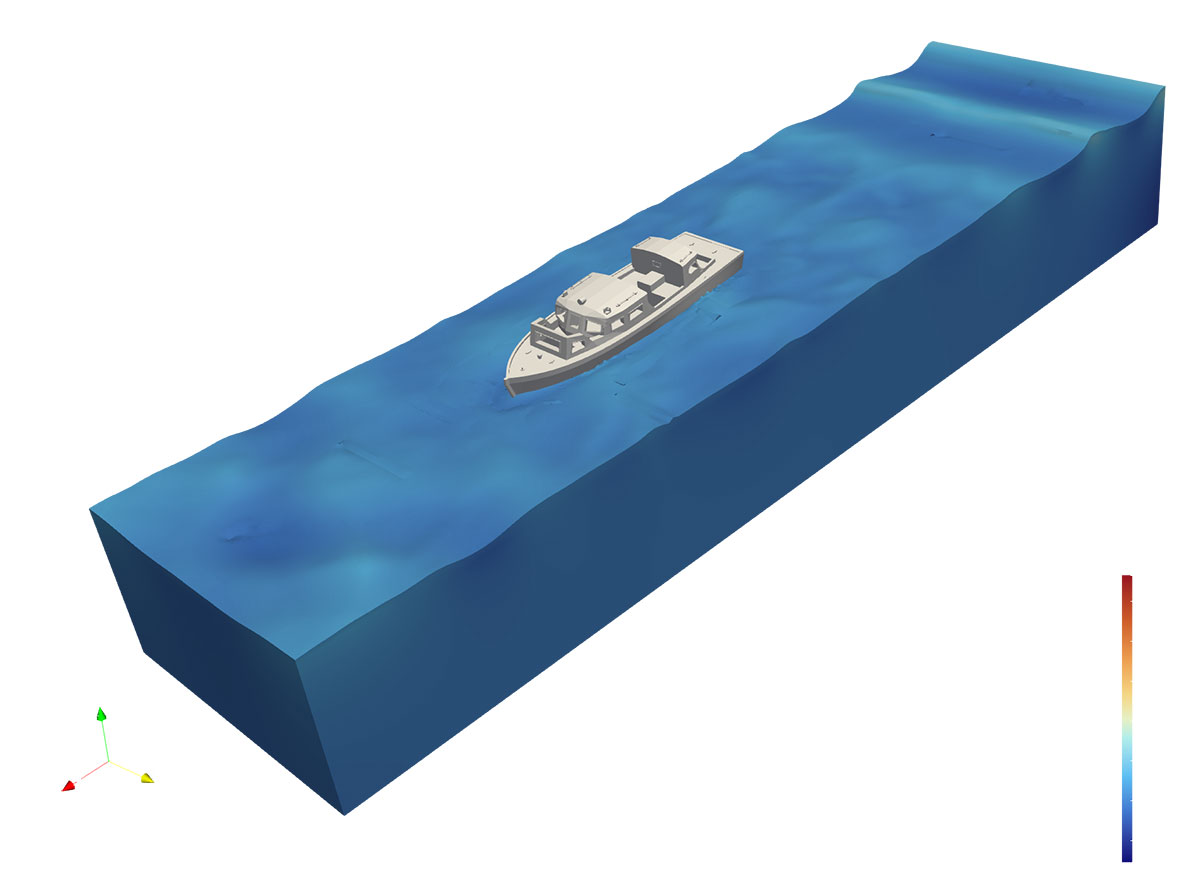

This figure shows an OpenFoam simulation of a boat inside a virtual wave tank. The application was created for Sandia National Laboratories’ Water Power Technologies Program. Applications like this can greatly reduce expenses – compared to either a physical wave tank or the manual creation of simulation inputs.

Frameworks used: SMTK, CMB, VTK, ParaView.

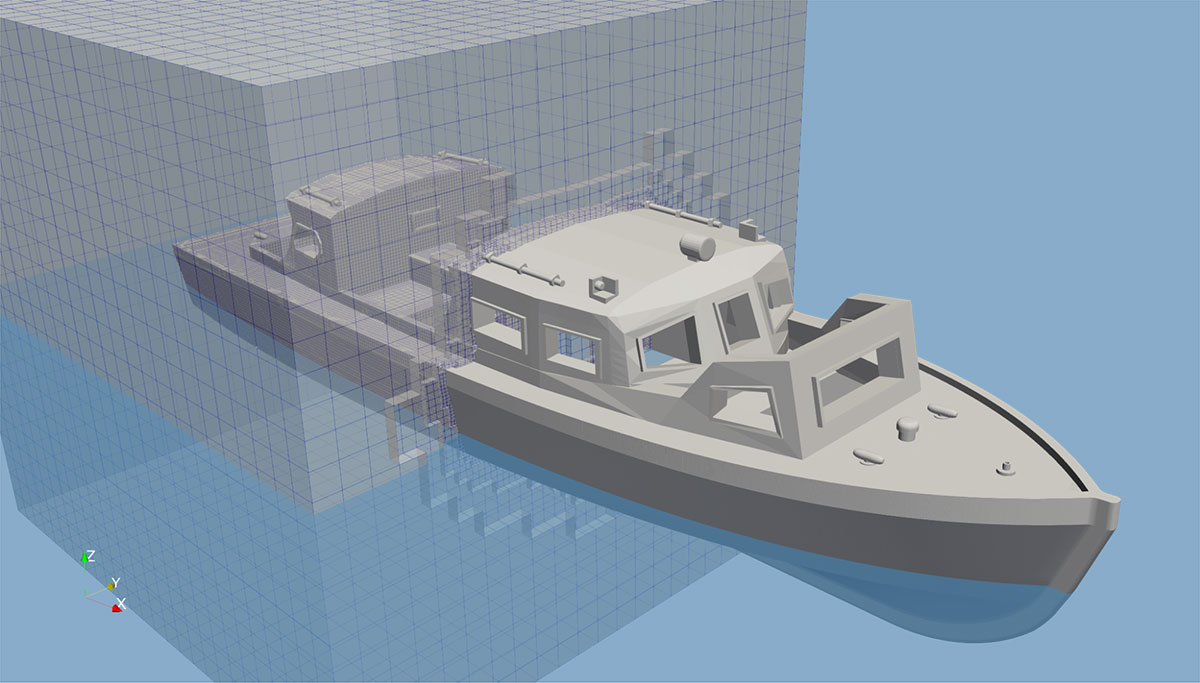

This figure shows an OpenFOAM workflow Kitware created for Sandia National Laboratories to evaluate the reactions of objects to wave motion. What’s shown is a ship being inserted into the tank. The box around the aft portion of the vessel is a preview of the OpenFOAM overset mesh (snapped to the ship exterior) that has been crinkle-clipped to reveal the forward part of the ship.This allows inspection of meshes before running a simulation.

Frameworks used: SMTK, VTK, ParaView

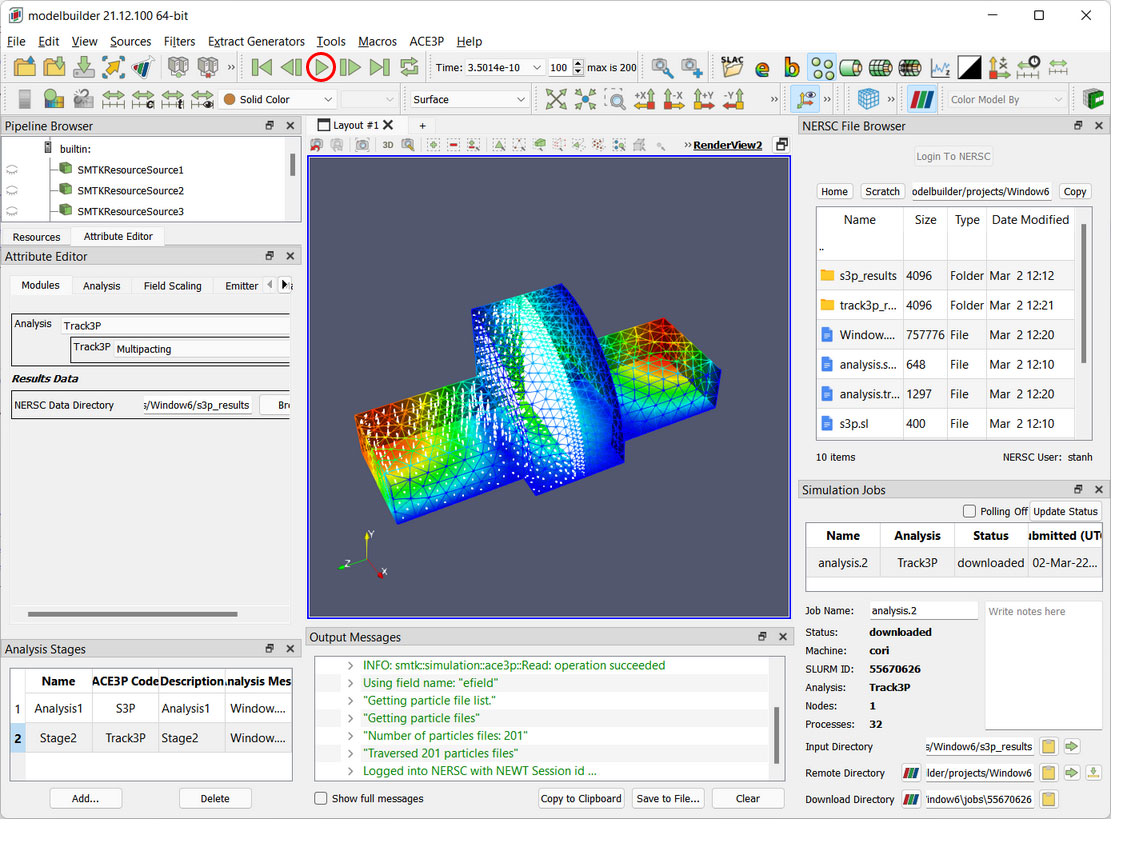

Simulation workflows often demand diverse computational resources. For instance, a high-energy physics workflow, leveraging SLAC’s Advanced Computational Electromagnetics 3D Parallel (ACE3P) tools, is employed in the design of particle accelerators and related instrumentation. In this scenario, the user initiates the workflow on their local machine, while the intensive computations are executed on the High-Performance Computing (HPC) resources at NERSC. Users have the flexibility to perform remote post-processing on the HPC machine or conveniently transfer results for local processing, all within the same integrated tool.

Frameworks used: SMTK, CMB, ParaView, VTK

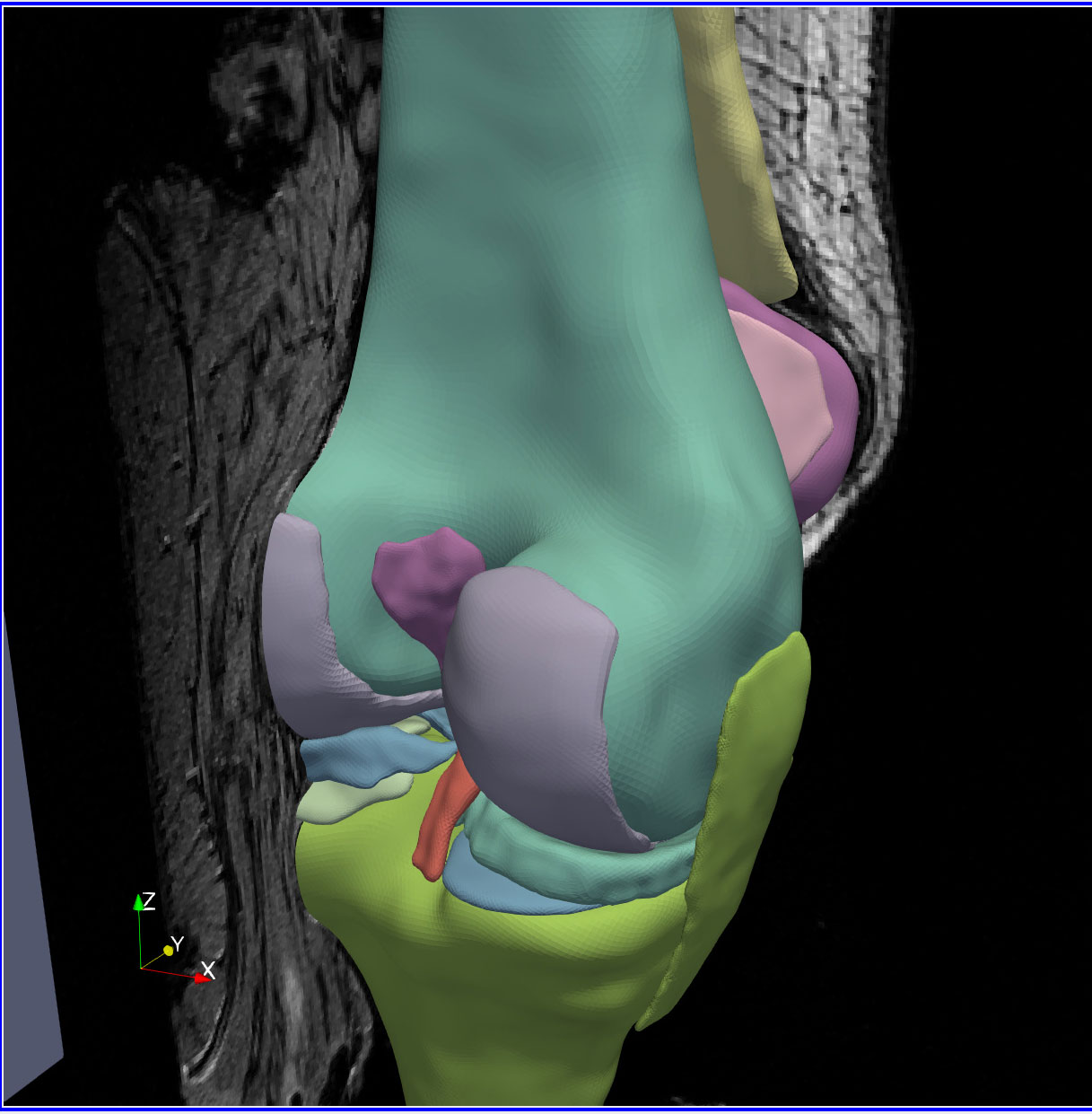

Developed for the Cleveland Clinic, this workflow showcases the intricate process of creating and annotating anatomical models. This involves segmenting and processing medical images and meshes. Users needed efficient ways to create and edit surface selections, remesh surfaces, and generate volumetric meshes from them, as well as to incorporate detailed ontologies into the annotation process.

Frameworks used: SMTK, CMB, ParaView, VTK

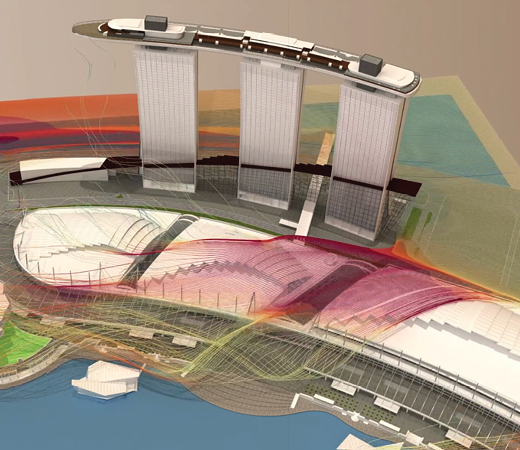

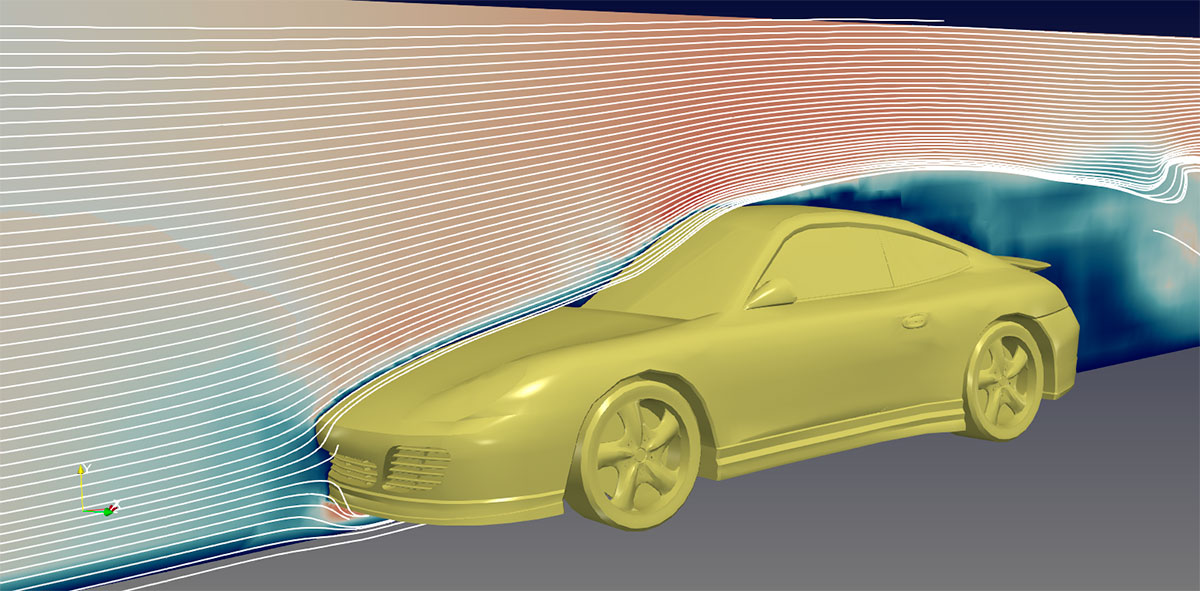

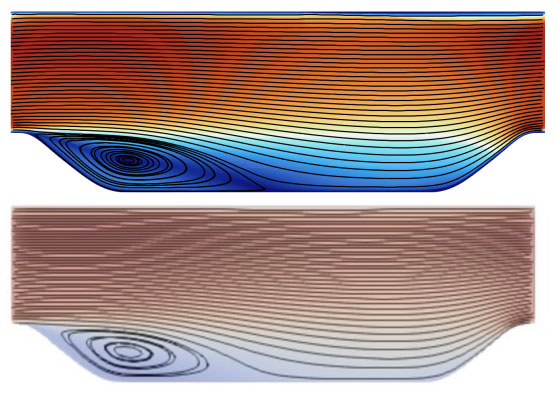

Computational fluid dynamics workflows, like OpenFOAM-based wind tunnel simulation shown above, require users to perform various tasks: problem setup, mesh generation, simulation processing, and post-processing. Decomposing these complex workflows into manageable, guided tasks is crucial for effective user management.

Frameworks used: VTK, CMB ParaView, SMTK.

Computational fluid dynamics (CFD) is integral to whole-body circulatory system workflows, supporting the development of new surgical procedures and patient health monitoring. These workflows often run continuously, necessitating in situ visualization for real-time observation by physicians and researchers.

The accompanying images illustrate work from the Randles Lab at Duke University, where methods for whole-body circulatory system simulation are being developed, modeling down to individual blood cells using the HARVEY fluid dynamics solver. The video showcases blood flow within a representative human aorta, originating at the ascending aorta, traversing the aortic arch, and concluding at the descending aorta. As the fluid enters the aortic arch, it diverges into the right and left subclavian and common arteries. To mimic in vivo circulation, the flow constantly pulses throughout the animation. Frameworks used: ParaView, ParaView Catalyst

Frameworks used: ParaView, Catalyst

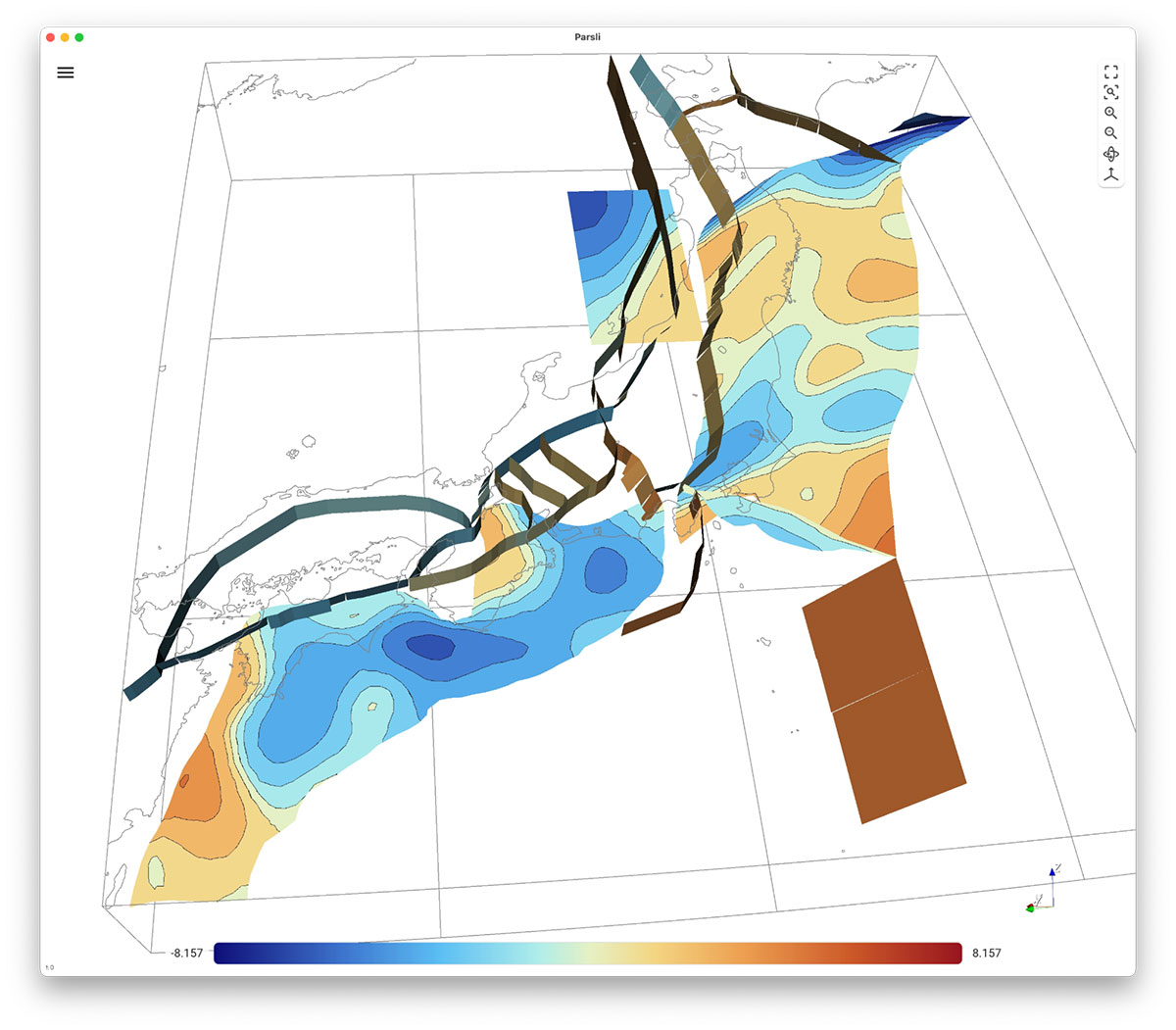

Parsli is a VTK-based viewer for fault system kinematics that enables rapid exploration and export of time-based animations. By leveraging advanced 3D graphics, interactive visualization, and high performance, we’ve transformed a workflow that once took days into one that now takes minutes—or even seconds—for initial validation and analysis. Its ease of use and installation has also encouraged the community to revisit past runs, uncovering phenomena that previously slipped through the cracks of the previous toolchain.

Frameworks used: Trame, VTK

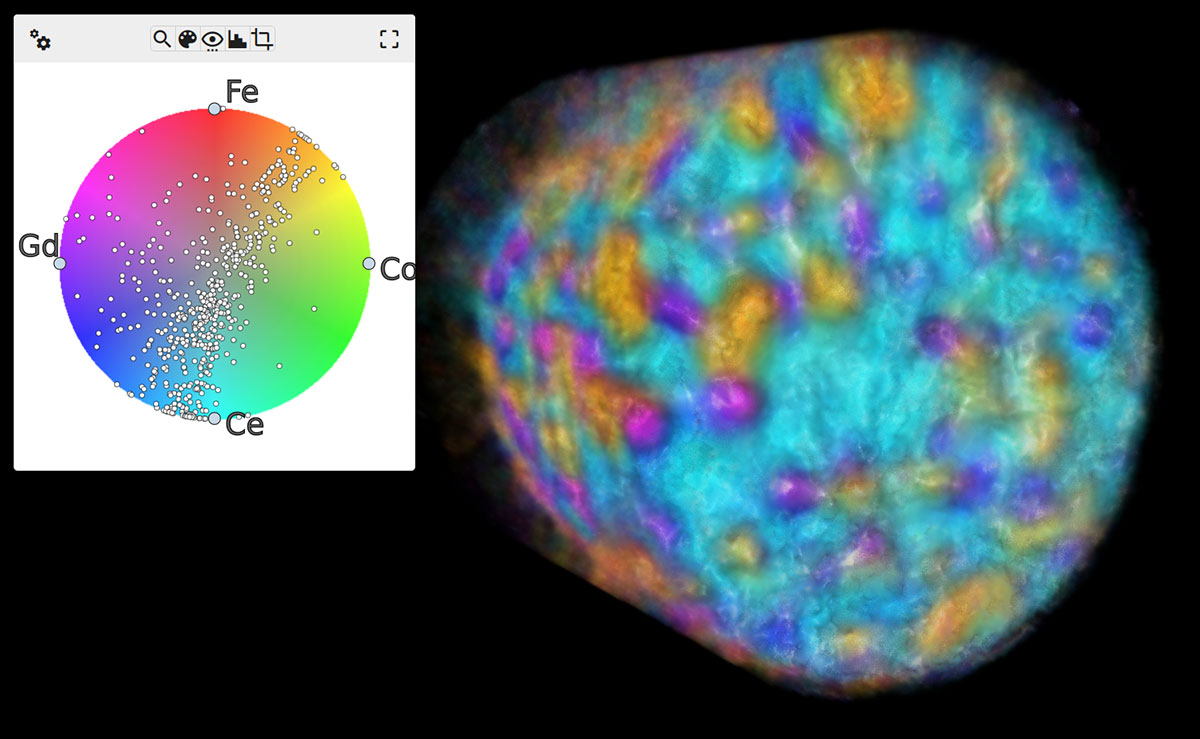

Visualizing and exploring multivariate/multimodal volumes, common in material modeling and medical simulations, demands innovative techniques. These techniques are crucial for revealing significant trends and effectively communicating discoveries to both domain experts and general audiences. As an example, the accompanying figure presents an x-ray fluorescence tomography dataset of a mixed ionic-electronic conductor (MIEC), analyzed using Kitware’s MultivariateView tool.

Frameworks Used: trame, VTK

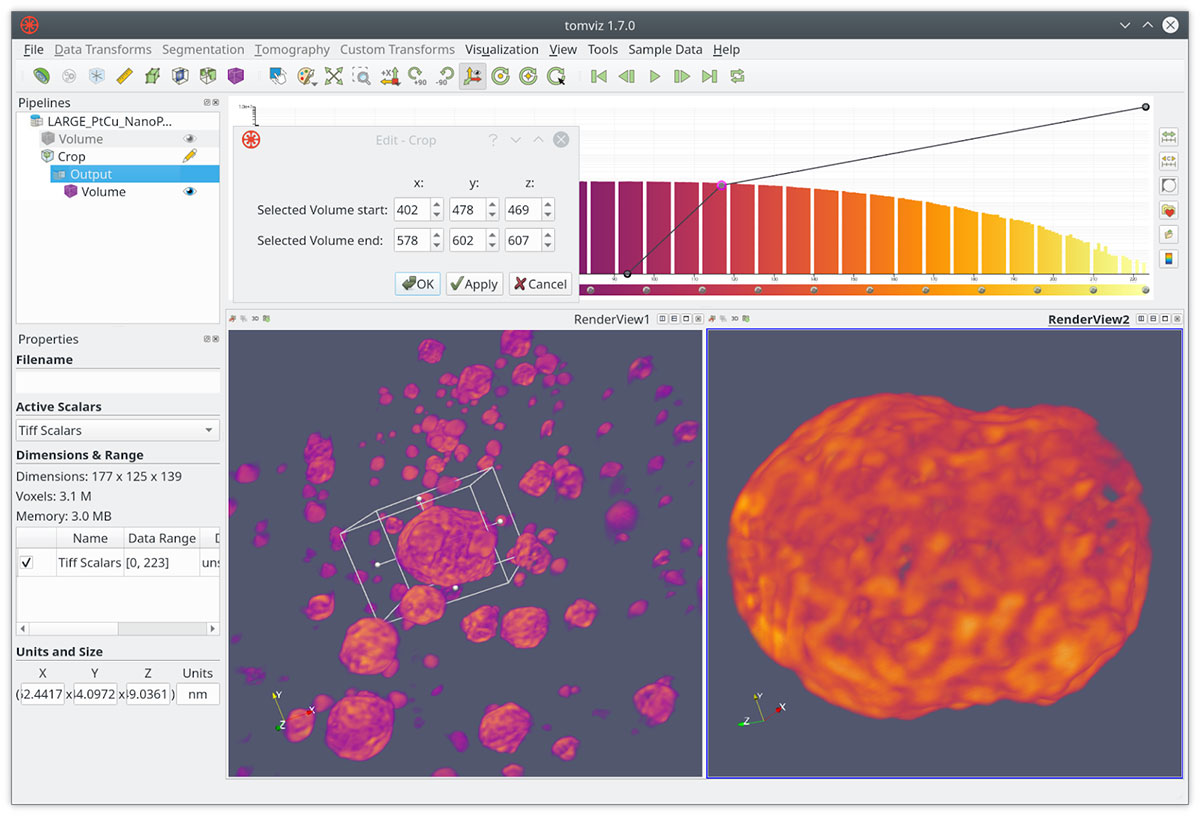

High-resolution 3D characterization is crucial for workflows in materials science and nanoscience. This requires advanced image processing, data analysis, visualization, and reproducibility. Integrating these features into a single environment streamlines the entire research pipeline, from raw data to publication-quality 3D renderings. Furthermore, incorporating capabilities like Python scripting and custom extensions expands its applicability to diverse workflows. Tomviz is an example that offers visualization, processing, and analysis for tomographic data. The image above from Tomviz demonstrates drawing a cropping region around 3D reconstructed PtCu nanoparticles, known for their effectiveness as fuel cell electrocatalysts.

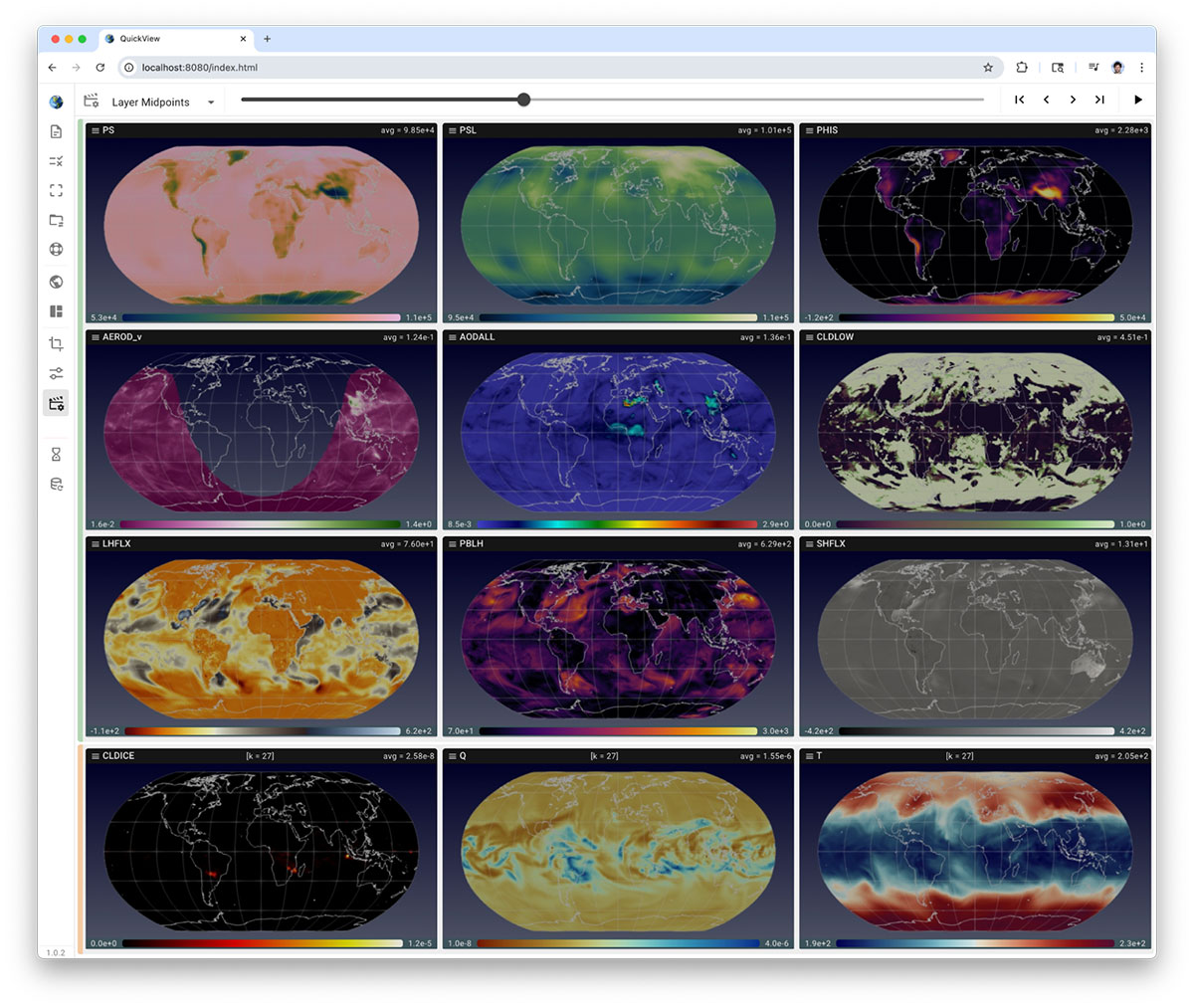

QuickView is a Trame + ParaView-powered tool for exploring atmospheric output from the E3SM Atmosphere Model (EAM). It provides an intuitive, no-scripting interface for multivariate visualization, model validation & verification and supports EAM v2, v3 (and in development v4) data formats – which simplifies the atmosphere modeling and analysis workflows.

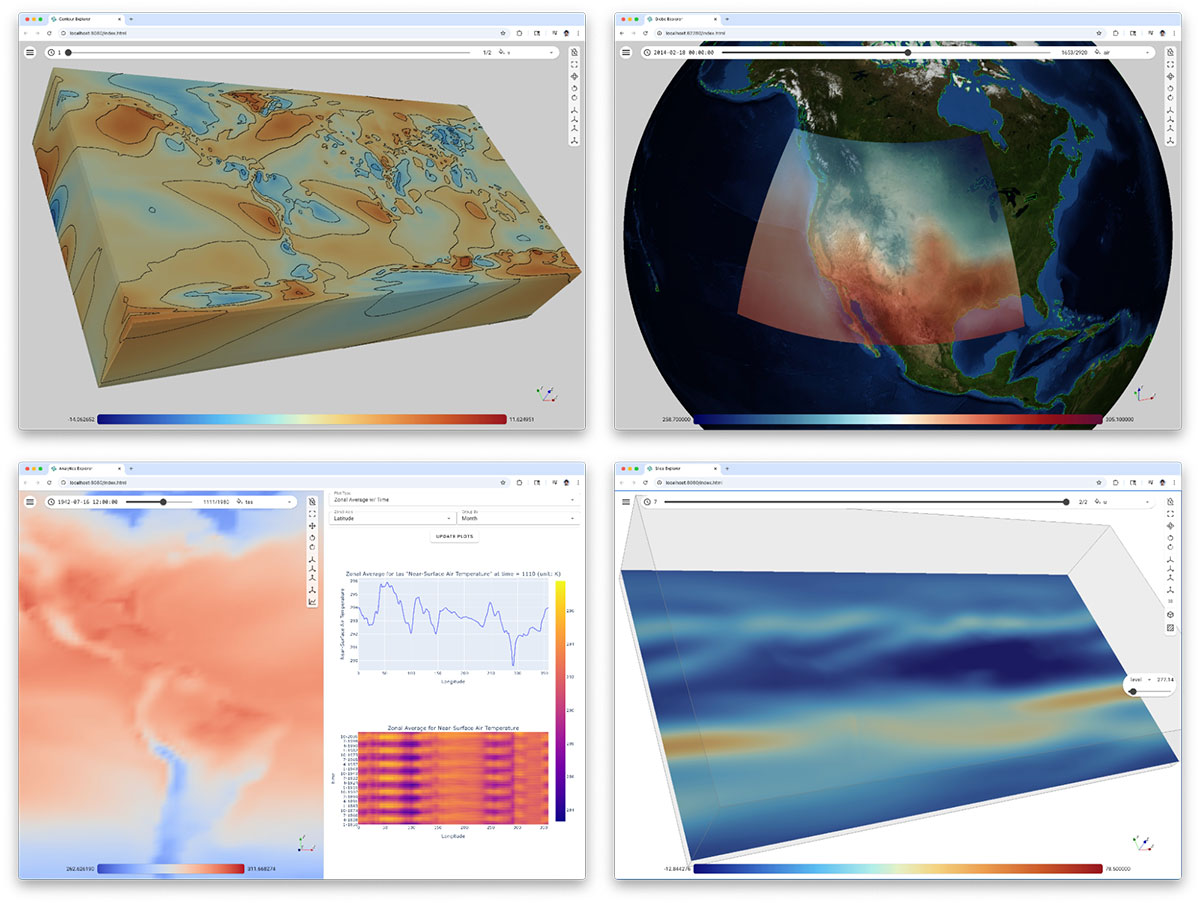

Pan3D is a fast, highly interactive visualization tool for Xarray datasets — a standard format for large, multidimensional arrays in climatology and other geospatial fields. Built on Trame and VTK, it leverages seamless interoperability between VTK and Xarray for efficient data exchange. A defining feature of Pan3D is its collection of Explorers (pictured above): lightweight, task-focused analysis apps that cut through the clutter of traditional, full-featured visualization tools such as ParaView. These explorers enable teams to craft bespoke, purpose-driven solutions, fostering collaboration and clear role separation.

Platforms: VTK and trame

In collaboration with NASA and the University of Colorado Boulder, Kitware is expanding the Catalyst in situ analysis platform to enable powerful AI models to access simulation data in memory at runtime for advanced model training and inference to improve upon existing simulation results. This approach empowers existing, validated simulation codes to leverage modern AI tools without complex and costly code integrations.

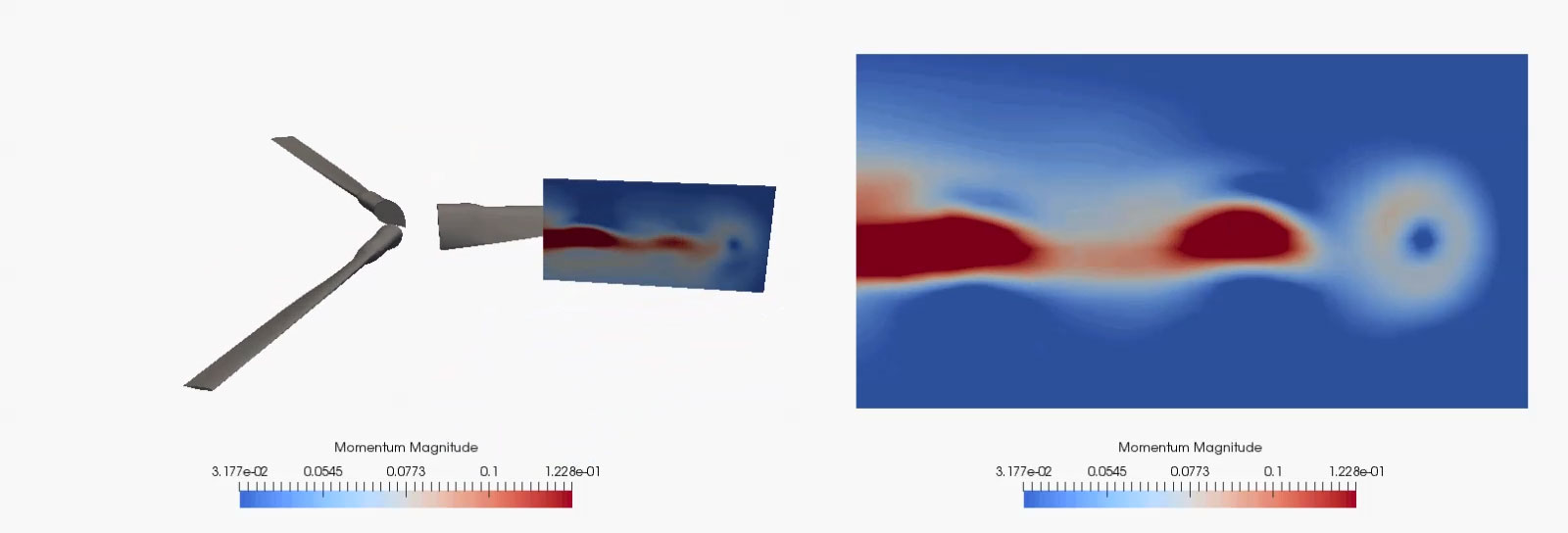

Rotorcraft simulation workflows present a complex, multidisciplinary challenge, as they necessitate the integration of moving-body aerodynamics with structural dynamics for rotor blade deformation, and vehicle flight dynamics and controls. Furthermore, the extensive data generated during a rotorcraft CFD simulation, stemming from numerous timesteps, can be substantial.

By incorporating in situ capabilities directly into the simulation workflow, developers and analysts can scrutinize crucial variables at each timestep, thereby avoiding the significant overhead associated with I/O and storage. This methodology not only optimizes HPC resource utilization but also facilitates real-time steering, swift validation, and more insightful diagnostics during protracted simulations. The accompanying images illustrate this approach using CREATE’s HELIOS framework, which leverages ParaView Catalyst for in situ visualization and analysis.

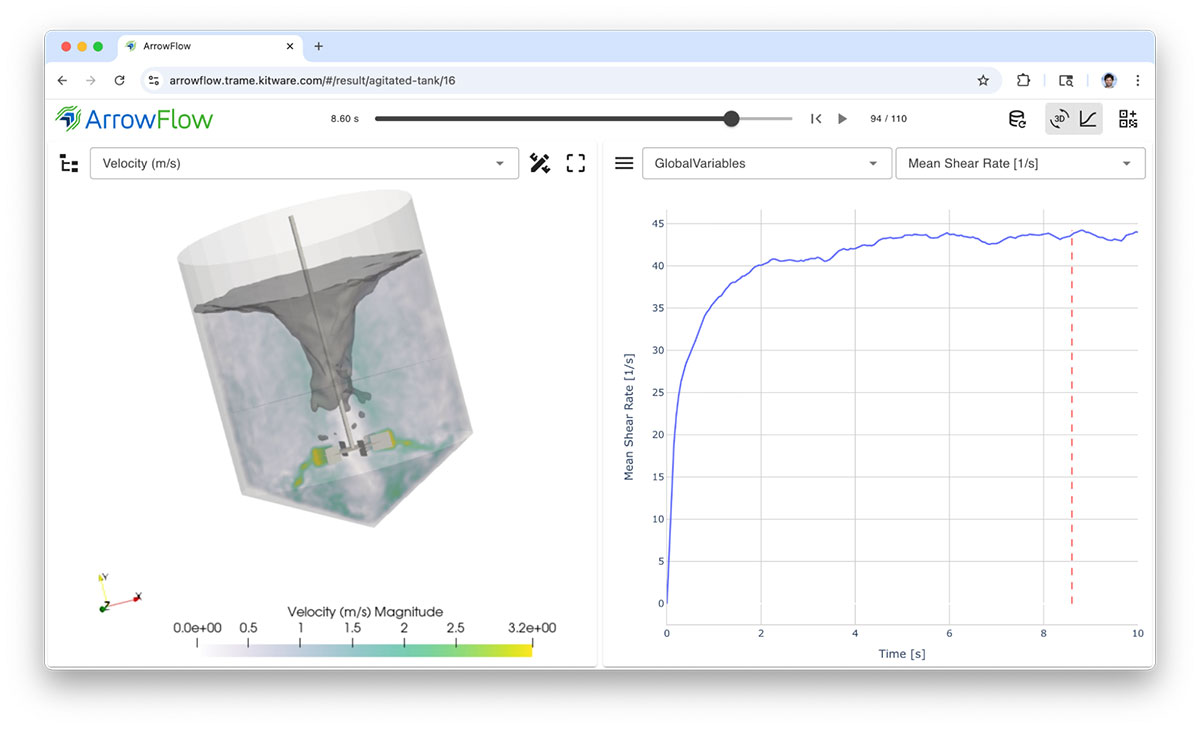

ArrowFlow, focuses on broadening simulation usage by allowing domain scientists to easily create templates and expose them to remote engineers. Its curated web interface for input simulation parameters and easy to use post-processing tools enables quick exploration for validation of settings to use with factory mixer, drier or any machinery setup into the system.

ArrowFlow relies on M-Star CFD™ for its solver and ParaView for its post-processing. Trame is exposing templates, solver and post-processing visualization in an easy to use solution.

Frameworks used: Trame, ParaView

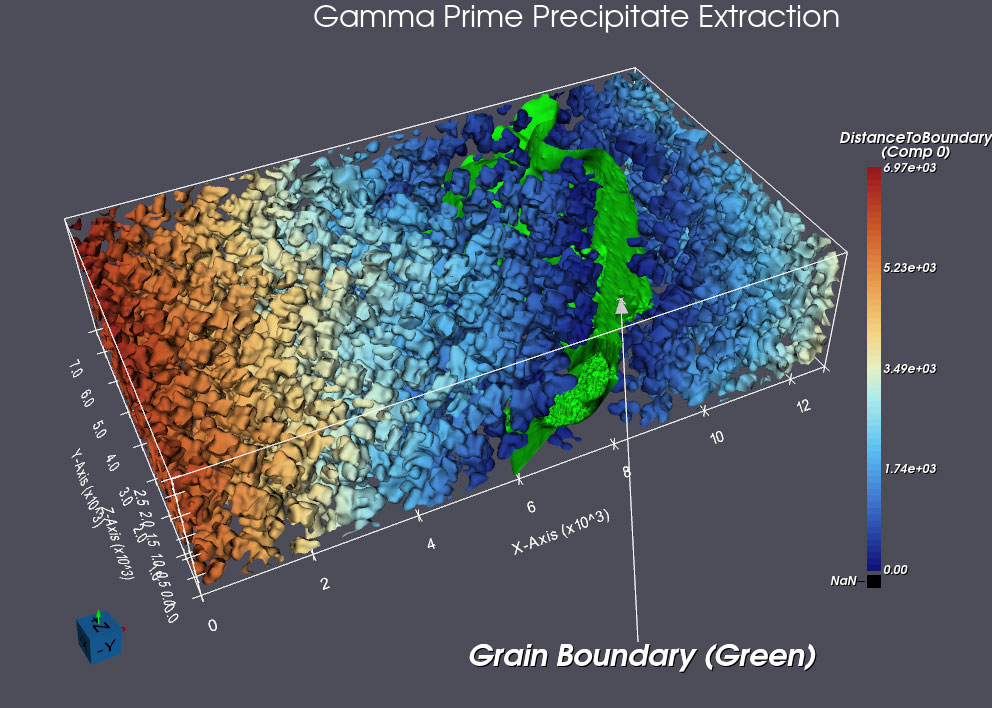

Displaying complex microstructural data is an integral part of many material science workflows and enables researchers to explore and understand the intricate geometries and properties of materials. This integration is crucial for analyzing simulated and experimental data, facilitating insights into material behavior, and accelerating the discovery of new materials with desired characteristics. The above image shows 3D precipitate morphology from a nickel based superalloy. Reconstruction was performed by DREAM3D-NX and subsequently visualized within DREAM3D-NX using VTK to provide advanced 3D rendering and visualization capabilities essential for material science research.

Acoustic modal analysis of a car cabin by

Undabit Acoustic Simulations. Identifying vibration modes that may impact acoustic properties is crucial, as acoustic resonances can amplify noise generated by the engine, a phenomenon often referred to as “booming.” Understanding the frequencies at which resonance occurs and the spatial distribution of the resonant field is essential. Visualization with ParaView’s advanced ray-tracing capabilities. Source:

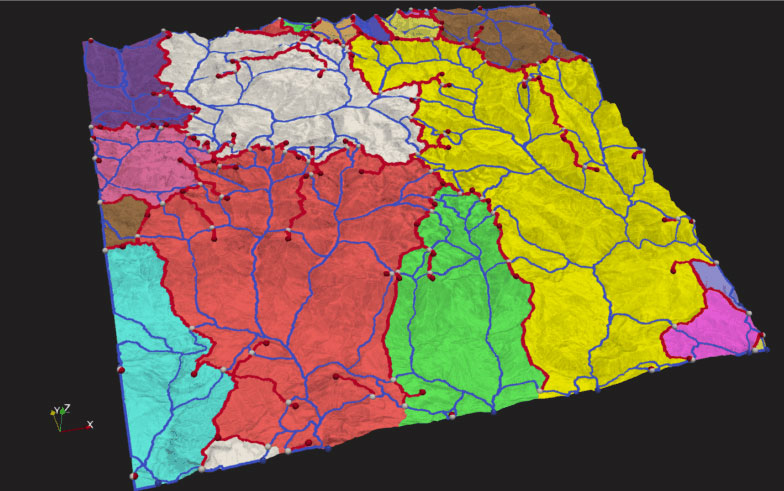

Automotive Acoustic Simulation Post-processing with ParaViewTopological analysis of terrain elevation is crucial for surface water workflows, such as estimating water runoff zones. This analysis allows for the identification and classification of critical points like peaks and pits, the segmentation of watershed boundaries, and the highlighting of ridges and valleys. These elements are essential for understanding the terrain’s structure. In the accompanying figure, colored regions indicate areas feeding into the blue river network, while red paths denote ridges. Platforms used: ParaView and its Topology Toolkit (TTK) plugin. For more information, see

Practical Use Cases for TTK.

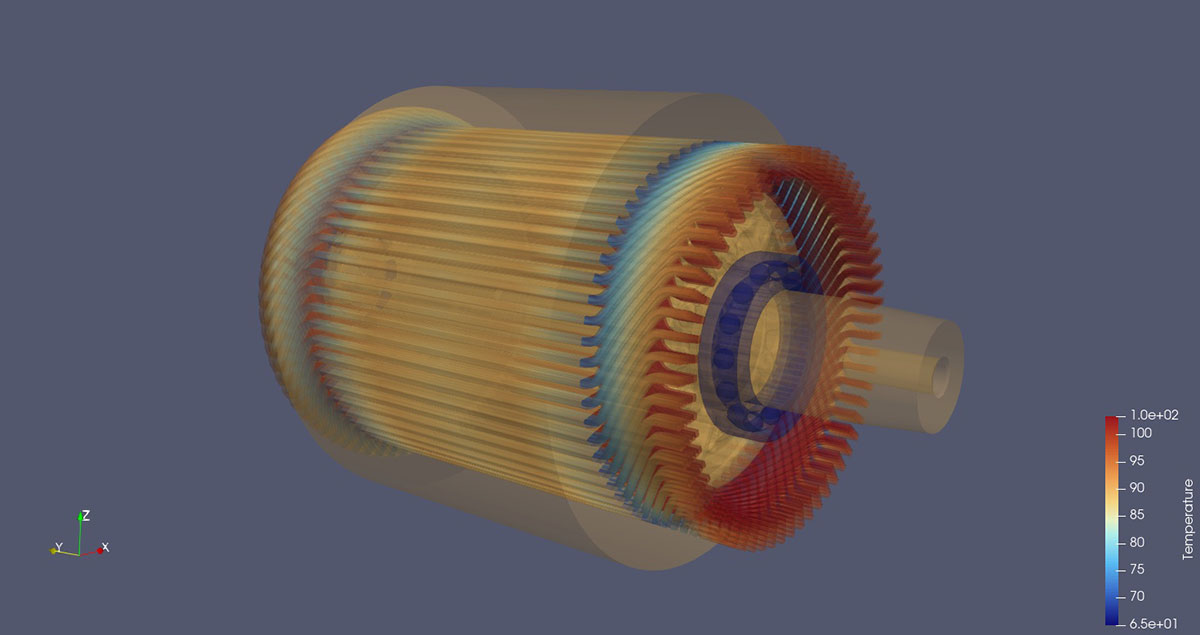

Live visualization of a drive train digital twin. Data from 30 temperature sensors on an electric motor are interpolated onto a digital twin model for live display in ParaView. This allows engineers from TotalEnergies to have direct access to a visualization showcasing the measured elements as it is running, and perform analysis and visualization within ParaView, either using the whole set of existing filters or even implementing their own. Platforms used: ParaView. More information at

Build, Control and Run Digital Twins with ParaView.

Partner with Kitware to Modernize Your HPC Workflows

As an industry leader in open source software and visualization frameworks, Kitware helps organizations bridge the gap between data generation and decision-making.

Our experts work with commercial partners to:

- Modernize existing HPC pipelines.

- Integrate AI and in-situ visualization for faster analysis.

- Develop secure, scalable, and future-ready visualization solutions.

Ready to accelerate your innovation?

Contact our experts to start the conversation.